Introduction

All of the manufactured products we use in our daily lives, from processed food to clothing and cars, are the result of production engineering. Production engineers need to have a comprehensive knowledge and understanding of all the possible production technologies available, their advantages and disadvantages, the requirements of the production system operation and the interaction between the various components of the production system.

This unit introduces students to the production process for key material types; the various types of machinery used to manufacture products and the different ways of organising production systems to optimise the production process; consideration of how to measure the effectiveness of a production system within the overall context of the manufacturing system; and an examination of how production engineering contributes to ensuring safe and reliable operation of manufacturing.

On successful completion of this unit students will be able to learn about the role and purpose of production engineering and its relationship with the other elements of a manufacturing system; most appropriate production processes and associated facility arrangements for manufacturing products of different material types; and designing a production system incorporating a number of different production processes.

Do You Need Assignment of This Question

Learning Outcomes

By the end of this unit students will be able to:

- LO1: Illustrate the role and purpose of production engineering and its relationship with the other elements of a manufacturing system.

- LO2: Describe the most appropriate production processes and associated facility arrangements for manufacturing products of different material types.

- LO3: Analyse how a production system can incorporate a number of different production processes for a given product or assembly.

- LO4: Explore the effectiveness of a production system in terms of its operation within the wider manufacturing system.

Essential Content

LO1 Illustrate the role and purpose of production engineering and its relationship with the other elements of a manufacturing system

Production engineering activities:

- Common practices for manufacturing

- Research and develop tools, processes, machines, and equipment

- Integrate facilities, production layout, and systems for producing quality products

- Design, implement and refine products, services, processes and systems, considering manufacture, assembly and end of life

- Use financial planning, recording and review processes and documentation, budgets, estimating, cost control, cost forecasting, and investment appraisal

- Application of quality system tools to support production engineering to include, Inspection strategies, Check Sheets, Fishbone Diagram, Histogram, Pareto Chart, Control Chart, Scatter Diagram and Process Flowcharts.

- Combination of manufacturing technology and management science.

LO2 Describe the most appropriate production processes and associated facility arrangements for manufacturing products of different material types

Production processes:

- Common ceramics, polymer, composite, and metals manufacturing processes

- The influence of mechanical and physical properties of the materials on the production process. Bonding and jointing technologies, including welding, adhesives, fasteners, locking and retaining methods, interference fits and mechanical assemblies.

Buy Answer of This Assessment & Raise Your Grades

LO3 Analyse how a production system can incorporate a number of different production processes for a given product or assembly

Function of the range of production facilities within a manufacturing plant:

- Production design for manufacture and assembly

- Cellular and flexible manufacturing systems

- Component production using CNC machining centres and automated production processes (single, batch, flow, mass)

- Automated materials handling equipment, conveyor systems, automatic guided vehicle servicing, product assembly and production lines

- Heat treatment facilities, paint and coating plants

- Warehouse, stock storage equipment

- The purpose, operation and effects of incorporating concepts such as lean manufacturing and just-in-time (JIT) supply to the production process

- Relevant manufacturing methods used and their applications, such as machining, joining, forming, assembling, shaping, processing, printing, moulding, extruding and casting.

LO4 Explore the effectiveness of a production system in terms of its operation within the wider manufacturing system

Production systems:

- Production performance criteria, through-put rates, yield rates, cost effectiveness, sustainability, flexibility and reliability

- Optimising supply chain performance and management

- Documentation control processes and procedures such as format, location, access, authorisation

- Production documentation management: job cards/build records, 2D & 3D drawing/models, Bill of Materials (BOM), Cost Analysis Reports, Compliance Report, Standard Operating Instructions (SOI’s), Standard Process Instructions (POI’s), Engineering Query Notifications (EQN’s) and Drawing Query Notifications (DQN’s)

- Use of Industry 4.0 tools/technologies and integration to promote effectiveness and operations (e.g. automation, robots, PLCs, digital systems and manufacturing engineering systems)

- Essential collaboration between manufacturer, supplier and retailer.

Production errors and rectification:

- Cost in terms of time, material waste, product recall, reputation and litigation

- Production data collection, critical evaluation and analysis; effective use of data collection systems and data formats.

The human component:

- Human factors. Impact of organisational, job and environment factors on individual performance, characteristics, and behaviours at workplace

- Cultural openness to new ideas and continuous improvement

- Technically savvy to encourage advanced/latest technologies for efficiencies including performance optimisation

- Collaboration and information sharing.

- Performance management and rewards

- Engineer training and development practices.

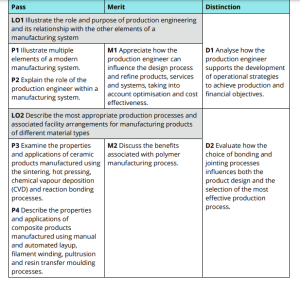

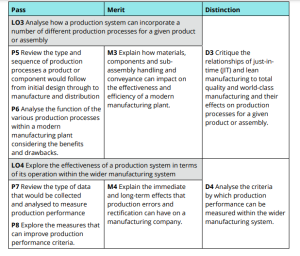

Learning Outcomes and Assessment Criteria

Are You Looking for Answer of This Assignment or Essay

Recommended Resources

Note: See HN Global for guidance on additional resources.

Print Resources

- Baudin M. and Netland T. (2023) Introduction to Manufacturing: An Industrial Engineering and Management Perspective. 1st Ed. Routledge.

- Burduk A., Batako A.D.L., Machado J., Wyczolkowski R., Dostatni E. and Rojek I. (Editors) (2023) Intelligent Systems in Production Engineering and Maintenance III − Lecture Notes in Mechanical Engineering (Paperback). Springer.

- Davim J.P. (Editor) (2016) Design of Experiments in Production Engineering. Springer International Publishing Switzerland.

- Durakbasa N.M. and Gencyilmaz M.G. (Editors) (2021) Digitizing Production Systems: Selected Papers from ISPR2021 − Lecture Notes in Mechanical Engineering (Paperback). Springer.

- Grote K.H. and Hefazi H. (Editors) (2021) Springer Handbook of Mechanical Engineering. Springer Nature.

- Groover M.P. (2020) Fundamentals of Modern Manufacturing: Materials, Processes, and Systems. John Wiley & Sons.

- Machado C. and Davim J.P. (Editors) (2022) Green Production Engineering and Management. 1st Ed. Woodhead Publishing.

- Mair G. (2019) Essential Manufacturing. Wiley.

- Phanden R.K., Kumar R., Pandey P.M., and Chakraborty A. (Editors) (2023) Advances in Industrial and Production Engineering: Select Proceedings of FLAME 2022 − Lecture Notes in Mechanical Engineering (Paperback). Springer.

Journals

Note: Example journals listed below provide a broad range of articles related to unit content and those relevant for the qualification. Staff and students are encouraged to explore these journals and any other suitable journals to support the development of academic study skills, and subject specific knowledge and skills as part of unit level delivery.

- Advances in Production Engineering and Management

- International Journal of Production Research

- Journal of Industrial and Production Engineering

- Management Systems in Production Engineering

- Production Engineering

Links

This unit links to the following related units:

- Unit 4023: Computer Aided Design and Manufacture (CAD/CAM)

- Unit 5015: Manufacturing Systems Engineering.

Do You Need Assignment of This Question

The post H/615/1488 Unit 4014: Production Engineering for Manufacture, BTEC Level 4 appeared first on Students Assignment Help UK.